Preventive Maintenance For Fleet Vehicles

Ensuring the longevity and efficiency of fleet vehicles is not just a routine task—it’s a crucial investment in the smooth operation of any transportation business. Preventive maintenance for fleet vehicles shouldn’t be seen as an optional measure but rather as a foundational strategy that enhances vehicle reliability, safety, and cost-effectiveness. Implementing a thorough maintenance schedule isn’t just about preventing breakdowns; it’s about optimizing performance and paving the way for long-term savings. In a world where every penny counts, adopting preventive maintenance not only extends the lifespan of your fleet but significantly boosts your business’s bottom line.

The Importance of Regular Maintenance Checks

Regular maintenance checks play an integral role in fleet management. By adhering to a structured preventive maintenance for fleet vehicles plan, businesses can avoid unnecessary downtime caused by unexpected repairs or breakdowns. The importance of such measures cannot be overstated. Consistent check-ups allow for the early detection of potential issues, ensuring that vehicles operate smoothly and safely. A well-maintained fleet also reflects positively on a company’s image, showcasing a commitment to safety and responsibility. Investing in preventative practices is a clear demonstration of foresightedness and dedication to quality service.

Timely maintenance reduces the risk of hefty repair bills and potential liabilities arising from vehicle malfunctions. When properly managed, preventive maintenance for fleet vehicles prevents disruptions in operations, ensuring consistent and reliable service delivery. Companies can maximize efficiency and foster trust with both clients and stakeholders by showcasing a commitment to maintaining high standards. Ultimately, the integration of regular checks and servicing into a fleet management strategy keeps vehicles—and business operations—running efficiently, promoting a culture of reliability and professionalism.

Advantages of Preventive Maintenance for Fleet Vehicles

1. Cost Efficiency: Implementing preventive maintenance for fleet vehicles drastically reduces unexpected repair costs. By addressing issues early, companies save money and allocate resources more effectively.

2. Improved Safety: Regular checks ensure all safety protocols are adhered to, minimizing the risk of accidents caused by mechanical failures.

3. Extended Vehicle Lifespan: Consistent maintenance prolongs the life of fleet vehicles, providing maximum return on investment and reducing the frequency of new vehicle purchases.

4. Enhanced Performance: Well-maintained vehicles perform optimally, leading to increased productivity and efficiency in operations.

5. Reduced Downtime: With fewer unexpected breakdowns, fleets spend more time on the road and less time being serviced, ensuring continuity in business operations.

Investing in the Future with Preventive Maintenance

In today’s competitive market, every advantage counts. Investing in preventive maintenance for fleet vehicles ensures that companies are not just keeping up with the competition, but setting the standard in efficiency and reliability. By proactively managing a fleet’s health, businesses lay the groundwork for long-term success. Establishing a comprehensive maintenance schedule is not an expense, but rather an essential investment that pays dividends in the form of reduced operational disruptions, lower costs, and increased vehicle longevity.

For fleet managers, the choice is clear; preventive maintenance is a proactive solution that arms businesses with the readiness to meet future demands head-on. Embracing this advantageous approach not only nurtures a fleet’s health but also fosters a robust operational framework capable of adapting to evolving industry challenges. By prioritizing preventive measures today, companies ensure a future where their fleets can perform at peak efficiency.

Key Components of a Maintenance Strategy

A comprehensive preventive maintenance for fleet vehicles strategy involves several critical components:

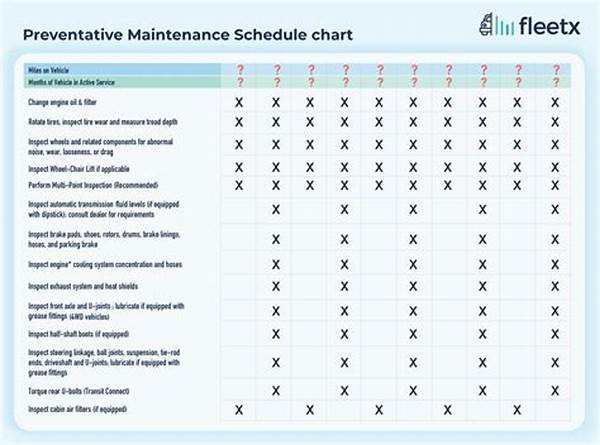

1. Scheduled Inspections: Regularly scheduled inspections ensure issues are identified before they become significant problems.

2. Maintenance Logs: Detailed logs help track vehicle history and streamline future repairs.

3. Staff Training: Educating staff on identifying potential issues can aid in early problem detection.

4. Use of Technology: Utilizing fleet management software improves scheduling and tracking, making maintenance more efficient.

5. Supplier Partnerships: Collaborating with parts suppliers ensures timely availability of necessary components for repairs.

6. Tailored Plans: Customizing maintenance plans to suit specific vehicle needs enhances their effectiveness.

7. Management Buy-in: Ensuring management understands and supports maintenance policies is crucial for effective implementation.

8. Regular Updates: Revisiting and updating maintenance strategies ensures they remain relevant and effective in meeting fleet needs.

9. Resource Allocation: Proper resource allocation for maintenance activities prevents unnecessary strain on operations.

10. Benchmarking: Comparing fleet performance metrics with industry standards helps identify improvement areas and optimize practices.

The Ripple Effect of Well-Maintained Fleet Vehicles

A commitment to preventive maintenance for fleet vehicles resonates beyond immediate business operations. It fosters an environment of care that permeates across company culture, influencing how staff perceive their roles and responsibilities. When vehicle maintenance is prioritized, employees feel safer and valued, knowing that their workplace prioritizes their well-being. This in turn encourages a more dedicated workforce, ready to contribute to the company’s success.

A meticulously maintained fleet also positions a company as a responsible market player. Clients and partners will view the organization as reliable and professional, fostering stronger business relationships and promoting customer loyalty. In an industry where reputation is paramount, preventive maintenance for fleet vehicles stands as a testament to a company’s commitment to excellence, therefore reinforcing trust and facilitating business growth.

Investing Today for Tomorrow’s Success

The narrative is clear: preventive maintenance for fleet vehicles is a smart business decision. Through proactive attention to vehicle care, companies are well-equipped to face the challenges of tomorrow. This approach reduces the burden of unexpected costs and supports a sustainable business model. Maintenance today paves the way for operational success, ensuring that fleets remain agile, reliable, and ready to meet customer demands.

Implementing this forward-thinking strategy not only secures the present but also sets the stage for future accomplishments. By making preventive maintenance a key part of their operational ethos, companies safeguard both their assets and reputation. With well-maintained fleet vehicles, businesses can drive confidently into the future, knowing they are backed by a dependable and efficient operational foundation.

A Comprehensive Overview of Best Practices

To ensure maximum benefits, companies must adopt best practices in preventive maintenance for fleet vehicles. These practices are grounded in regular assessments and strategic planning. Regular checkups assess the condition of essential parts and systems, preventing costly repairs and ensuring operational integrity. Ultimately, a disciplined approach to maintenance results in improved safety, reliability, and efficiency.

Investing time and resources in a well-structured maintenance program pays off significantly. Regular updates to maintenance policies, engaging staff in training initiatives, incorporating innovative technology solutions, and benchmarking performance metrics against industry standards are crucial steps in optimizing maintenance efforts. Businesses that integrate preventive maintenance for fleet vehicles into their operational strategies enjoy the dual benefits of reliability and improved business outcomes.